The post Improving Cold Storage Efficiency and Productivity appeared first on Johnson Equipment Company.

]]>When it comes to preserving the cold-chain integrity of products in the distribution cycle, managing and controlling the climates of products is integral to your business and reputation. Regulatory agencies have been cracking down in recent years – especially the FDA with the implementation of the Food Safety Modernization Act (FSMA) in 2011, and the implementation of the 2017 FDA Food Code. The scrutiny of inspectors has become more and more strict, and this trend is set to continue into the foreseeable future. Along with the increasing demands of regulatory agencies, consumer expectations have risen, and in today’s competitive market it has become more important than ever to protect your company’s product integrity and reputation. Although expectations for cold-chain integrity and food and beverage handling have risen, these expectations may be effectively met while also reducing the high costs of cooling cold-storage facilities by minimizing cooling loss and properly separating and controlling environments within your facility.

Cold Storage Solutions

FasTrax FR Highspeed Door

FR Highspeed Door

We are proud to offer a line of high-speed cold storage doors, adaptable to a variety of  different applications and configurations – doors which effectively separate and control environments within your warehouse, while enhancing the safety of both pedestrians and forklift drivers within your facility. As we like to say, “doors are meant to be closed.” This means, especially in cold storage applications, doors must be shut as much as possible and as quickly as possible in order to cut operational costs of cooling, and to protect the integrity of products.

different applications and configurations – doors which effectively separate and control environments within your warehouse, while enhancing the safety of both pedestrians and forklift drivers within your facility. As we like to say, “doors are meant to be closed.” This means, especially in cold storage applications, doors must be shut as much as possible and as quickly as possible in order to cut operational costs of cooling, and to protect the integrity of products.

Our FasTrax FR Highspeed Door provides a perfect solution – insulating product and operating at high speeds, while improving safety and communications at access points within your facility. Like the rest of the FasTrax door line we offer, the FasTrax FR highspeed freezer door is constructed with a soft bottom-edge curtain and Soft Breakaway

FR Highspeed Door provides a perfect solution – insulating product and operating at high speeds, while improving safety and communications at access points within your facility. Like the rest of the FasTrax door line we offer, the FasTrax FR highspeed freezer door is constructed with a soft bottom-edge curtain and Soft Breakaway technology which leads the industry in allowing safe impactability. Additionally, the FasTrax

technology which leads the industry in allowing safe impactability. Additionally, the FasTrax FR leads the industry in operating speeds of up to 100’’ per second – ensuring that even in busy traffic areas, your freezer environments are separated and controlled – providing energy savings from increased cooling efficiency while also protecting your products. The door’s curtain system combines unique Thermal-Flex Sealing with the R-4 InsulMax curtain construction to ensure energy savings and efficiency in the most demanding applications. These doors’ low-profile, versatile track design allows for track configurations to fit nearly all possible situations.

FR leads the industry in operating speeds of up to 100’’ per second – ensuring that even in busy traffic areas, your freezer environments are separated and controlled – providing energy savings from increased cooling efficiency while also protecting your products. The door’s curtain system combines unique Thermal-Flex Sealing with the R-4 InsulMax curtain construction to ensure energy savings and efficiency in the most demanding applications. These doors’ low-profile, versatile track design allows for track configurations to fit nearly all possible situations.

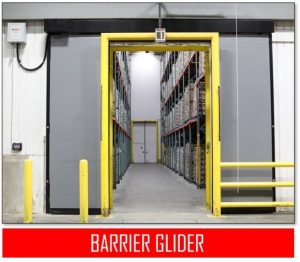

Barrier Glider Freezer Door

Freezer Door

Another solution is our unique bi-parting Barrier Glider Freezer Door. Like

Freezer Door. Like  the FasTrax, the Barrier Glider

the FasTrax, the Barrier Glider is built with safe, impactable, auto-reversing technology. The impactable, 3’’ insulated Iso-Tek

is built with safe, impactable, auto-reversing technology. The impactable, 3’’ insulated Iso-Tek door panels move at speeds up to 80’’ per second, allowing the same high-speed access as the FasTrax, and maximizing time the door is sealed. Like the FasTrax FR, the Barrier Glider is equipped with a NEMA 4x GUI touchscreen control center which allows for easy and simple diagnostics, settings, and troubleshooting. The door can be configured with a variety of different customizable activation methods to best suit your space and traffic flow.

door panels move at speeds up to 80’’ per second, allowing the same high-speed access as the FasTrax, and maximizing time the door is sealed. Like the FasTrax FR, the Barrier Glider is equipped with a NEMA 4x GUI touchscreen control center which allows for easy and simple diagnostics, settings, and troubleshooting. The door can be configured with a variety of different customizable activation methods to best suit your space and traffic flow.

Implementation of our line of freezer doors is an easy, simple solution to improve safety, productivity, and efficiency within your facility – while supporting the cold-chain integrity of your operations. We would love to meet with you and learn more about your operations to understand your needs and find the best solution for your space. Using our Energy Savings calculator, we can give you a ROI calculation for your potential energy savings, and partner with you in determining the best course of action for your facility in protecting your cold-storage environments. As innovators in the industry, we have years of experience working with and satisfying our partner’s needs. The possibilities are endless.

For more information about maximizing your energy consumption while improving efficiency and productivity within your facility, contact your local Johnson Equipment. We look forward to developing our business partnership and learning more about your operations in order to properly protect your personnel and assets.

The post Improving Cold Storage Efficiency and Productivity appeared first on Johnson Equipment Company.

]]>The post Loading Dock Drive Approach Design Policy & Products appeared first on Johnson Equipment Company.

]]>Why is loading dock approach design important?

OSHA has identified semi-tractor trailers as the second leading cause of back over fatalities in the United States. Noise, Limited visibility, lack of communication, heavy equipment, and a push for productivity create a variety of hazards for people outside of the loading dock. Getting caught in or compressed by trucks or equipment costs $1.95 billion in U.S workers compensation each year.

According to OSHA, the fatal injury rate for the warehousing industry is higher than the national average for all industries. Many of these fatalities occur at the loading dock. Though some companies claim to have a drive approach policy in place, with truck drivers, maintenance workers, sub-contractors, visitors, etc., it’s impossible to keep all foot traffic away from the loading dock. Reasons someone might be in harm’s way on the ground outside of the facility include opening trailer doors, chocking tires, lowering landing gear, placing trailer stands, and maintaining dock equipment.

Loading Dock Drive Approach Products

The Approach-Vu System

The Approach-Vu system from Rite-Hite is one solution to this problem. The Approach-Vu

system from Rite-Hite is one solution to this problem. The Approach-Vu system is a module which integrates a motion sensor with a light and horn system to present a clear visual and audible warning to pedestrians in the drive approach when a backing vehicle is detected. The module is mounted on the center-line, above the exterior door opening. The lights and horn are mounted below the exterior dock door opening or in the vehicle restraint housing. Approach-Vu

system is a module which integrates a motion sensor with a light and horn system to present a clear visual and audible warning to pedestrians in the drive approach when a backing vehicle is detected. The module is mounted on the center-line, above the exterior door opening. The lights and horn are mounted below the exterior dock door opening or in the vehicle restraint housing. Approach-Vu is focused on the safety of foot traffic outside of the facility. These light communication systems are integrated into Rite-Hite’s Dok-Lok

is focused on the safety of foot traffic outside of the facility. These light communication systems are integrated into Rite-Hite’s Dok-Lok vehicle restraint line, but the Approach-Vu

vehicle restraint line, but the Approach-Vu system may also be added as a standalone unit with a standalone control box.

system may also be added as a standalone unit with a standalone control box.

The Lok-Vu System

Another safety solution is Rite-Hite’s Lok-Vu , which utilizes a single or dual outside camera view which is displayed inside. The single camera helps to confirm the dock restraint is securely engaged, while a dual camera configuration also helps to confirm a trailer stand’s presence. Lok-Vu

, which utilizes a single or dual outside camera view which is displayed inside. The single camera helps to confirm the dock restraint is securely engaged, while a dual camera configuration also helps to confirm a trailer stand’s presence. Lok-Vu is mounted adjacent to or below the exterior dock door opening.

is mounted adjacent to or below the exterior dock door opening. Through application of Rite-Hite’s Approach-Vu

Through application of Rite-Hite’s Approach-Vu and/or Lok-Vu

and/or Lok-Vu systems, companies will greatly improve dock safety for those who may find themselves at the outside of the loading dock, thus reducing the risk for injury or death. Nearly 25% of all facility injuries occur at the loading dock. Many of these are due to trucks not being locked in properly or at all, allowing for movement of the truck (both intentionally and unintentionally) throughout the loading/unloading process. Rite-Hite’s Approach-Vu

systems, companies will greatly improve dock safety for those who may find themselves at the outside of the loading dock, thus reducing the risk for injury or death. Nearly 25% of all facility injuries occur at the loading dock. Many of these are due to trucks not being locked in properly or at all, allowing for movement of the truck (both intentionally and unintentionally) throughout the loading/unloading process. Rite-Hite’s Approach-Vu and Lok-Vu

and Lok-Vu systems gives workers inside the facility the ability to confirm the truck is properly secured before the process ever begins.

systems gives workers inside the facility the ability to confirm the truck is properly secured before the process ever begins.

For more information on protecting your dock position, facility floor space, your employees, and company equipment – contact your local Johnson Equipment office. We look forward to developing a business partnership with you and learning more about your operations in order to properly protect your personnel and assets.

The post Loading Dock Drive Approach Design Policy & Products appeared first on Johnson Equipment Company.

]]>The post How To Meet Food Grade Warehouse Safety & Sanitation Standards appeared first on Johnson Equipment Company.

]]>Your facilities must meet the standards of FDA and USDA inspections and requirements – but more importantly your concern is providing quality, sanitary products to your respective customers and distributors while protecting your employees and assets.

In order to meet your needs, and the demands of regulatory agencies, Johnson Equipment is proud to offer a full spectrum of products in compliance with the standards of the FDA, USDA, and AIB. Our goal is to partner with you to meet and exceed these standards – by improving the food safety of your products while protecting your employees and company property.

Recent Changes in Food Grade Warehouse Standards

In 2011, the FDA rolled out the Food Safety Modernization Act (FSMA) in order to prevent contamination and protect the safety of employees. This act requires all food and beverage manufacturing, processing, or storage facilities to register with the FDA, and undergo inspection. These facility inspections recur at five-year intervals. The 2017 FDA Food Code specifically lists the requirements to pass these inspections.

- FDA 6-202 .15 – OUTER OPENINGS, PROTECTED: Outer openings of a food establishment shall be protected against the entry of insects and rodents by:

- Filling or closing holes and other gaps along floors, walls, and ceilings; closed, tight-fitting windows; solid, self-closing, tight fitting doors.

- If the windows and doors of a food establishment are kept open for ventilation or other purposes, the openings shall be protected against the entry of insects and rodents by:

- 16 mesh to 25.4mm (16 mesh to 1 inch) screens; Properly designed and installed air curtains to control flying insects.

The above provision of the FDA code requires facility managers to ensure that all gaps and openings that would allow outside contamination into the building must be covered, and all “white light” eliminated. This is especially crucial around your dock positions and door openings – areas with gaps between the leveler and the top edge of the pit, and door positions opened for trailer unloading. In order to eliminate these gaps at the dock and door position, Johnson Equipment Company offers a line of solutions inside and outside dock position in accordance with FDA Food Code 6-202.15.

Improve Food Grade Warehouse Safety & Sanitation Outside of Your Facility

When a truck is present in the loading dock position, gaps around the trailer are exposed when the dock door is opened. The Rite-Hite Eclipse® Dock Shelter is the solution to this problem – fitted with durable GapMaster hooks which wrap around swing-open trailer doors, and seal hinge gaps. Additionally, the unique head curtain of the Eclipse Dock Shelter applies over 100 pounds of pressure across the full width of the trailer top – ensuring that gaps above and on either side of the trailer are sealed. Existing dock seals and shelters may be equipped with the Rite-Hite Raingard® RG-3000 Header Seal, mounted over to the top of the header. This seal applies the additional force of 100 pounds to the top of the trailer, and eliminates wet, slippery conditions at the dock position, mitigating the entry of foreign contaminants. The Rainguard® RG-3000 is specifically designed to withstand harsh environmental conditions, and extend the lifetime of your dock seals or shelters.

When the dock leveler is raised into the bed of a trailer for loading, a new gap is created underneath the leveler – allowing debris and contamination to enter the pit area. Rite-Hite’s PitMaster® is an efficient option Johnson Equipment provides in order to seal the gaps that the dock leveler pit presents. The PitMaster® V Seal seals off these gaps in the same way in vertical leveler applications. In addition, open gaps at dock leveler corners also allow unwanted elements to enter and expensive energy to escape – a problem solved with the application of PitMaster® Lip Corner Seals. Paired with the Eclipse shelter, the PitMaster seals complete a total seal around the trailer – eliminating the “white light” gaps.

Improve Food Grade Warehouse Safety & Sanitation Inside of Your Facility

As the FDA Food Code 6-202.15 states, exposed gaps in the floor and in the walls must be covered or sealed as well – and this includes the gap between the top edge of the pit and the dock leveler.

Around the dock door and leveler, there may still be small gaps on the inside of your facility which allow foreign material to enter. Gaps under the dock door can be eliminated through the combination of the Gap-Sealr and the Wedg-It

and the Wedg-It from Rite-Hite. The Gap-Sealr

from Rite-Hite. The Gap-Sealr , mounted to the bottom of the door, seals uneven surfaces below the door, while the addition of the Wedg-It

, mounted to the bottom of the door, seals uneven surfaces below the door, while the addition of the Wedg-It fills the gap between the leveler, the dock pit wall, and the bottom edge of the sectional door. The Rite-Seal

fills the gap between the leveler, the dock pit wall, and the bottom edge of the sectional door. The Rite-Seal brush seal completes the seal around the doors side and bottom edges – mounted near the tracks of the door in order to seal door gaps when a trailer is not present. These solutions provide the answer to the FDA requirements of sealing or covering wall gaps or openings.

brush seal completes the seal around the doors side and bottom edges – mounted near the tracks of the door in order to seal door gaps when a trailer is not present. These solutions provide the answer to the FDA requirements of sealing or covering wall gaps or openings.

Johnson Equipment also provides the application of products engineered to seal gaps in the deck of the dock leveler. The Lanyard Cup Seal, attached to the chain of the leveler, stops air penetration through the leveler. Gaps around the perimeter of the leveler edge are eliminated with the application of the Leveler Weather Seal.

Finally, the Rear Hinge Seal covers the gap at the back of the leveler plate above the leveler hinge. This complete line of products protects your facility from foreign contamination, provides energy savings through climate control, and fully meets all standards of FDA Food Code standard 6-202.15.

In addition to sealing and covering all gaps in and around the walls and floors of your facility, the AIB (American Institute of Baking) recommends further measures in order to maintain cleanliness, and eliminate pests. The Sanitary Design chapter within their literature on Food Safety and Sanitation recommends maintaining an 18-inch perimeter between the wall and any stored product or raw material. This is to allow for proper inspection, cleaning, and maintenance of pest monitoring and control devices on the perimeter of your facility.

“Food safety standards recommend providing an 18-inch perimeter between the wall and any stored product or raw material to allow for inspections, cleaning, and maintenance of pest monitoring devices…. Maintaining floor perimeters is an important element for any food plant’s product safety program.”

These perimeters help protect your product and add an extra layer of protection to your facility.

Our goal is to partner with you in going above & beyond and meeting and exceeding industry standards. For more information on the above solutions, contact your local Johnson Equipment Representative. We look forward to partnering with you in creating a clean, safe, and efficient workplace environment.

The post How To Meet Food Grade Warehouse Safety & Sanitation Standards appeared first on Johnson Equipment Company.

]]>The post Improve Warehouse Safety with Blue Lights for Forklift Trucks appeared first on Johnson Equipment Company.

]]>OSHA’s regulation for Powered Industrial Trucks, §1910.178 (h)(2), states:

“[w]here general lighting is less than 2 lumens per square foot, auxiliary directional lighting shall be provided on the truck.”

While §1910.178 standard does not specifically require flashing lights or back-up beepers, employers have a duty under the OSH Act, 29 U.S.C. § 654 (a)(1), also known as the General Duty Clause, to furnish employment and a place of employment, free from recognized hazards that are causing or a likely to cause death or serious physical harm to employees, where employees are exposed to hazards, including but not limited to, struck by, caught-in-between and crushing by the forklift.

B56.1-2009 shows that the industry recognizes this hazard and that equipping trucks with sound-producing and visual devices are feasible means to abate this hazard. An employer whose workplace presents this hazard and has not taken feasible steps to mitigate this hazard may be in violation of the General Duty Clause.

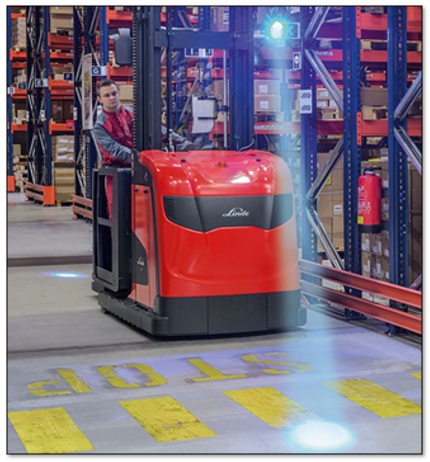

How Blue Lights Improve Forklift Truck Safety

The notion of blue LED forklift safety lights initially gained traction in the United States around 2013, but it had been seen in other countries before then. These blue lights glide across the floor, approximately 15 feet in front of or behind the forklift, giving pedestrians and other traffic an improved visual warning. These blue lights drastically improve in-plant safety, yet each year more than 100,000 forklift accidents continued to occur. Many of these accidents are a result of poor communication at busy intersections and blind corners throughout the facility. The blue lights on forklifts only give a 1.7 second reaction time to those in its path, which isn’t nearly enough time considering the speed at which these vehicles move. In response, Rite-Hite has developed two blue light communication devices to further enhance safety within the facility.

Blue Light Forklift Safety Products

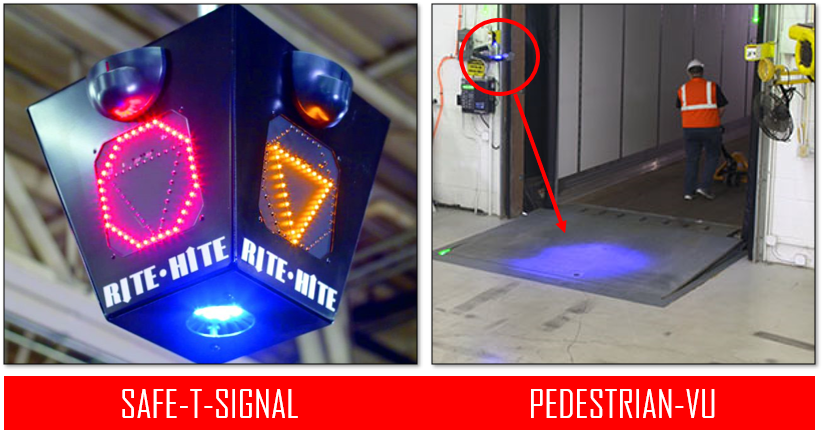

Rite-Hite Safe-T-Signal

Rite-Hite’s ceiling mounted Safe-T-Signal, which detects traffic activity and displays an intense blue flashing light onto the intersection, is a great option for reducing forklift accidents inside the facility. This product provides pedestrians and other forklift drivers a larger window of warning, by alerting them to proceed with caution when the blue light is visible.

The Safe-T-Signal is available for 2-way, 3-way, and 4-way intersections. When oncoming traffic has been detected from one direction, all other directions not in the detection zone will be presented with a yellow “yield” triangle. When traffic is detected from two or more directions, directions with traffic will be presented with a red “stop sign” octagon and directions without traffic will be presented with yellow “yield” triangles, as well as a blue LED light illuminating the floor. Lastly, when traffic is detected from all directions, all directions will be presented with a red “stop sign” octagon and a blue LED light illuminating the floor. These features provide improved communication for everyone near blind-spotted intersections, which will greatly reduce the probability of an accident.

Rite-Hite Pedestrian-Vu

At the loading dock, another viable solution is Rite-Hite’s Pedestrian-Vu. This can be used as a standalone unit or can be integrated with a Dok Lok Style Light Communication Box. Pedestrian-Vu helps detect activity inside of the trailer by utilizing sensors on each side of the dock door, which are aimed inside the back of the truck. If movement is detected, an intense blue flashing light projects onto the dock leveler as a signal to lifts and pedestrians, warning them to proceed with caution.

Learn more about improving warehouse safety with an effective blue light safety policy by contacting us today.

[contact-form-7]The post Improve Warehouse Safety with Blue Lights for Forklift Trucks appeared first on Johnson Equipment Company.

]]>The post Loading Dock Safety Barriers: Rite-Hite vs. Clopay Safe-T-Shield appeared first on Johnson Equipment Company.

]]>Loading Dock Barrier OSHA Regulations

According to OSHA documentation, 95,000 employees are injured every year while operating forklifts, and in 2012 workplace injuries and deaths cost companies a total of $200 billion. OSHA studies show that 7% of all forklift-related accidents occur within a warehouse when a lift is driven off the loading dock position. This occurs because of exposed dock positions – which at a height of 48’’ pose a risk of serious injury to both pedestrians and forklift drivers, especially considering each dock position is crossed an average of 100,000 times per year. In order to combat the high risk associated with fall injuries from dock positions, in January of 2017 OSHA added regulation 1910.28(b) which requires fall protection across exposed openings and walkways. In compliance with these regulations, Johnson Equipment is excited to offer a line of practical solutions to mitigate the risk of forklifts and personnel exiting a dock position.

Top Loading Dock Safety Barriers

Rite-Hite Dok-Guardian vs. Clopay Safe-T-Shield

The Dok-Guardian line from Rite-Hite and the Clopay Safe-T-Shield are both practical answers to this problem – both providing fall protection from exposed dock positions.

The Dok-Guardian Loading Dock Barrier Line

The Dok-Guardian HDXL and Dok-Guardian LDXL have the stopping power of up to 30,000 and 5,500 pounds respectively. As a result, the Dok Guardian HDXL has the stopping power to halt a forklift’s movement and prevent it from falling off a dock position or damaging the door. Rite-Hite’s Dok Guardian systems offer a high-visibility PVC coated mesh curtain, which is anchored on either side of the dock position by safety wardens and serve the dual purpose of protecting the door track from impact damage. The curtain automatically retracts when unhooked from the engaged position and is stored in the opposite safety warden. Both systems meet and exceed OSHA requirement 1910.29 for walking and working surfaces.

The Clopay Safe-T-Shield

The Clopay Safe-T-Shield is capable of withstanding outward and downward forces of 200 pounds on the top rail, 150 pounds at the mid rail, and 50 pounds at the toe board in order to protect warehouse personnel in accordance with OSHA standards 1910.28 and 1910.29. This pedestrian shield is mounted on a rolling track in front of the dock door, so that it may be brought down when the dock position is exposed and returned to its position above the header when the loading dock is in use.

For more information on protecting your dock position, facility floor space, your employees, and company equipment – contact your local Johnson Equipment representative. We look forward to developing a business partnership with you and learning more about your operation in order to properly protect your personnel and assets.

The post Loading Dock Safety Barriers: Rite-Hite vs. Clopay Safe-T-Shield appeared first on Johnson Equipment Company.

]]>The post Improve Warehouse Cooling Without Air Conditioning appeared first on Johnson Equipment Company.

]]>Texas, Oklahoma, Louisiana, Arkansas, and Tennessee have some of the hottest summer climates in the county, which is why we have been exploring products and services to develop the best cooling solution for our customers, without the need for air conditioning. We have established a partnership with two key manufacturers, focusing on 3 specific product lines, in order to bring you the most efficient method of creating air flow and cooling effect for your warehouse.

How to cool a warehouse without ac:

By combining fans and exhaust systems from various suppliers and customizing the position of these products to your warehouse’s unique configuration, we’re able to effectively cool large warehouses without air conditioning, even in the hottest summer climates in the United States.

Essential Warehouse Cooling Products & Services

The High Volume – Low Speed Revolution Fan

The first product line we recommend is the HVLS (High Volume Low Speed) Revolution Fan, a product that will have all of your people buzzing due to its size and unique aesthetic. With sizes from 8’ to 24’, The HVLS Revolution Fan produces the most airflow in the industry, backed by 3rd party testing. This is ideal for large open areas around the loading dock, in production areas, and in some aisle ways. The specially engineered contour blade design allows airflow to travel down as well as outward to ensure airflow reaches stagnant dead spots that other products tend to miss.

The High Volume Revolution Fan

The second product line also utilizes size but produces a higher velocity airflow. The high velocity is perfect for long runs such as aisle ways, pedestrian walkways, and catwalks. As tested by our team and backed by manufacturer testing, one fan can create up to 7 mph of airflow at 200’ away from the fan placement. By utilizing a large blade diameter, we can typically cover runs as wide as 15’. An additional key feature are bi-directional louvers that ensure air moves at the proper angle but also shields spinning blades from inadvertent forklift impact.

The Supply Exhaust Product

The third and last product line focuses on supply and exhaust methods for applications that require air exchange for maximum cooling effect. The idea of creating a supply of air at one end of the building and exhaust at the other, is not a new one, but when used in conjunction with the rest of our product lines, airflow is significantly increased over traditional installations.

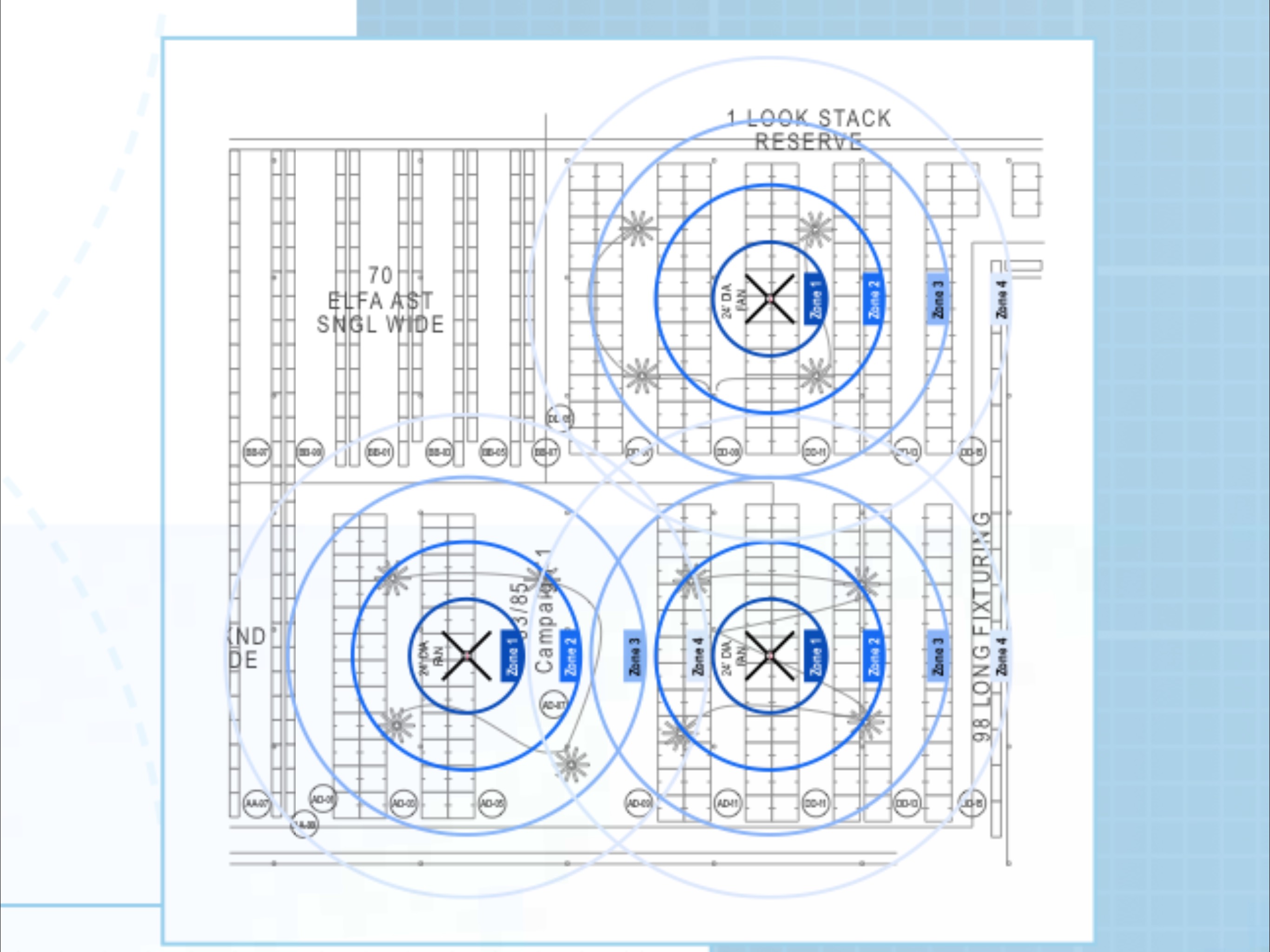

Your Local Customer Service Representative

The final ingredient to creating maximum airflow in your facility is our team of local customer service representatives that will walk your facility and sit down with you to understand your expectations and budget. They will then utilize drawings of your facility and application engineers to create a Fan Planner document that will show the layout of the fans along with expected airflow velocity in mph.

The post Improve Warehouse Cooling Without Air Conditioning appeared first on Johnson Equipment Company.

]]>The post Industrial Doors appeared first on Johnson Equipment Company.

]]>The post Industrial Doors appeared first on Johnson Equipment Company.

]]>The post Dock Lock & Truck Restraints appeared first on Johnson Equipment Company.

]]>The post Dock Lock & Truck Restraints appeared first on Johnson Equipment Company.

]]>